|

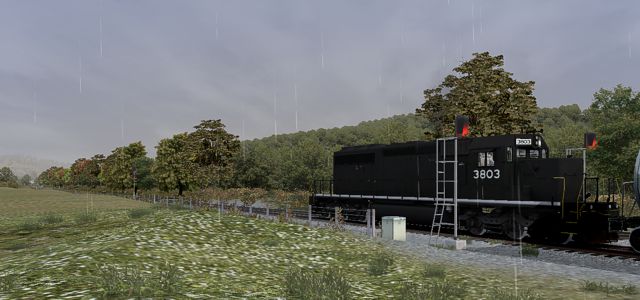

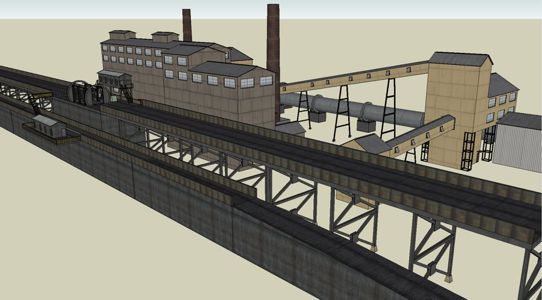

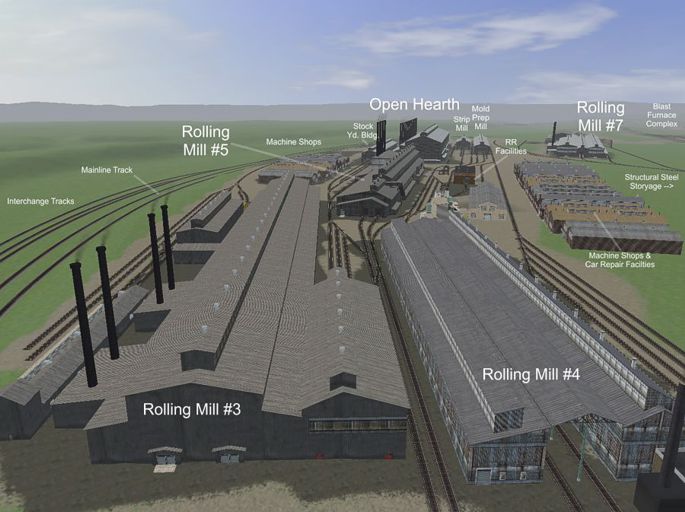

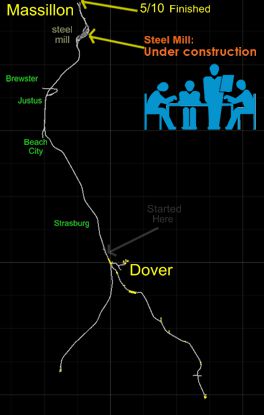

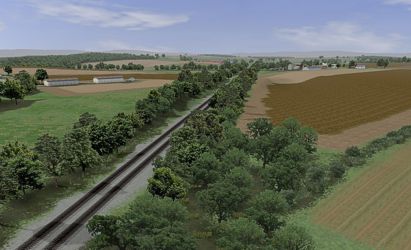

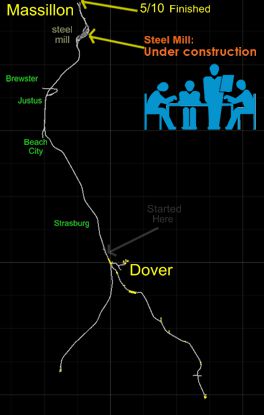

5/10: The last of the "rough draft" for the Dover to Massillon extension of Ohio Steel is finished. The past few days have focused on the scenery north of the Massillon Steel Mill where interchange and drop-offs are made in what

is an intense urban environment. From here there is still much to do but next week will concentrate on the construction of parts of the steel mill, especially the blast furnace. Other aspects of the route not normally done while in

rough draft made will commence as well.

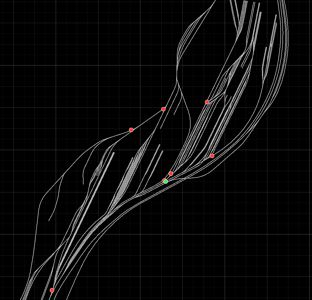

5/5: The last remaining tiles of the extension have been reached and scenery placement in these tiles has already begun. This area is of interest as three railroads intersected at this junction. One line, I believe once PRR,

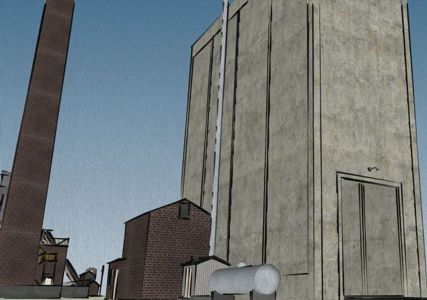

extends east and will hopefully be the focus of the next extension. And to of all places, Canton - Ohio. A large steel mill populates Canton and features a modern and still "in use" Basic Oxygen Furnace. A massive structure, to put mildly,

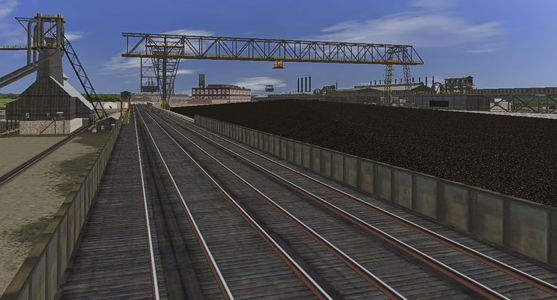

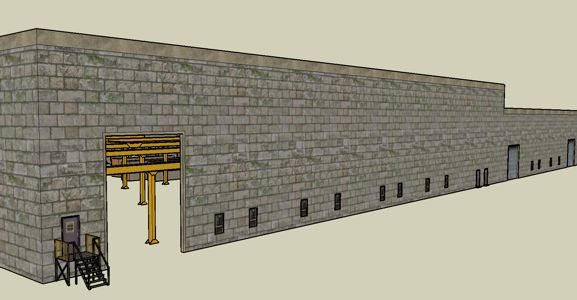

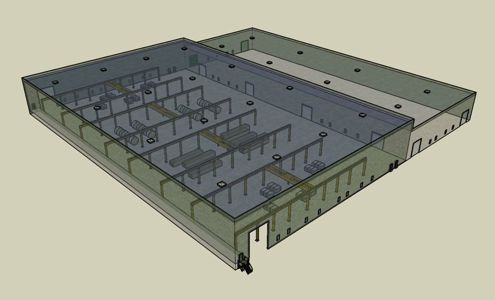

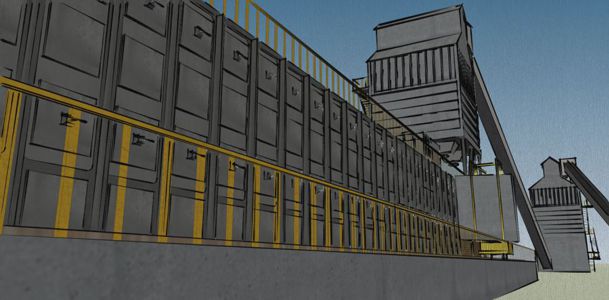

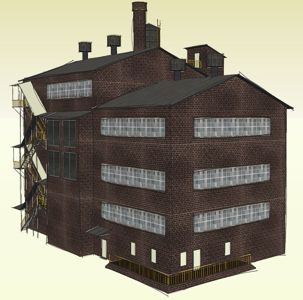

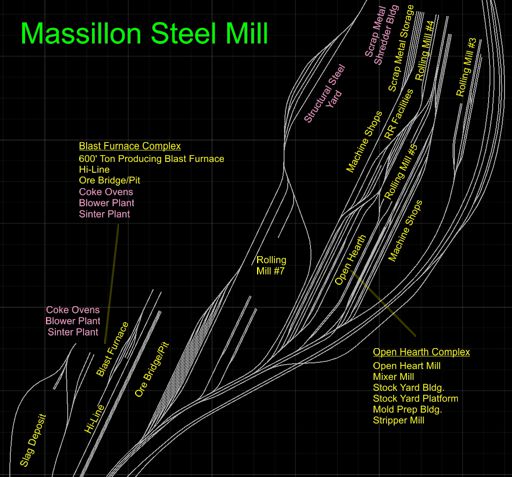

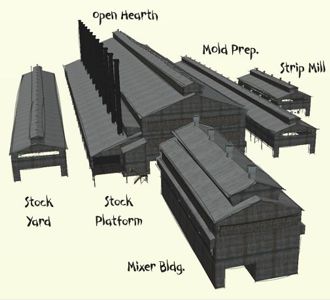

it dwarfs the Massillon blast furnace which in its day was rated for only 600 tons per day, built possibly around 1926. Concerning the Massillon Steel Mill, this week, besides studying plans for the blast furnace, I've also acquired

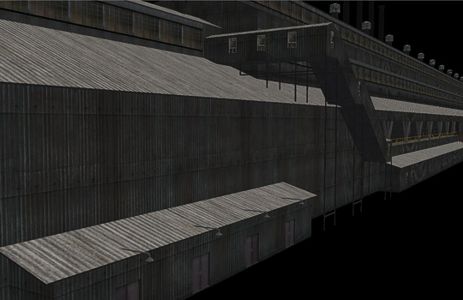

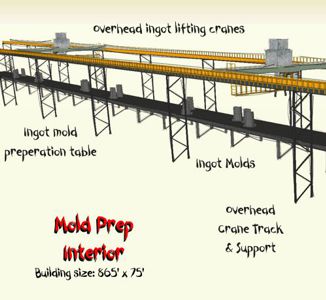

plans for an Open Hearth. The Open Hearth has opened up a whole new front in getting the Massillon Steel Mill to be more authentic. More trackage as well as the building itself will have its own extensions to include a Mold yard,

Stock building and platform and a Ingot Stripping building. The amount of learning and detail that goes into the making if not the operation of an Open Hearth Mill is about as steep as that of a blast furnace. Stay tuned as more news

to come in the finishing days of the Massillon extension to Dover.

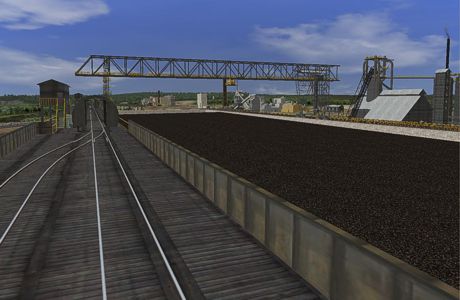

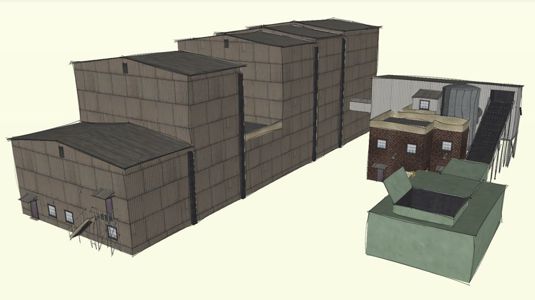

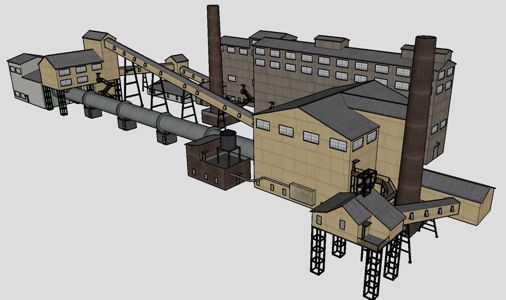

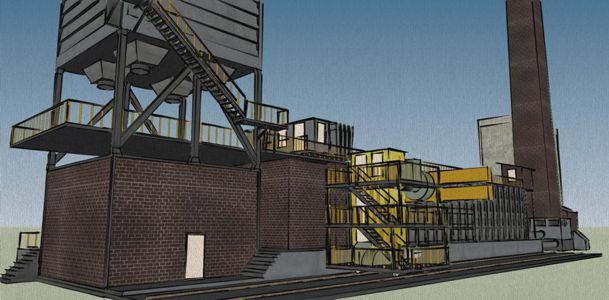

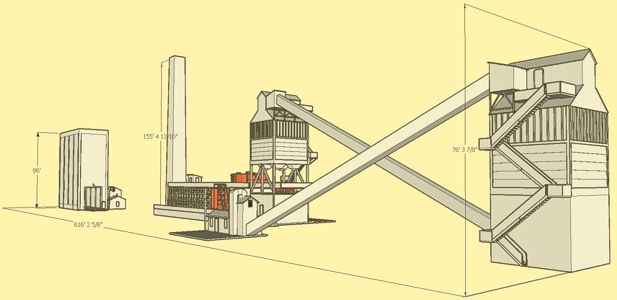

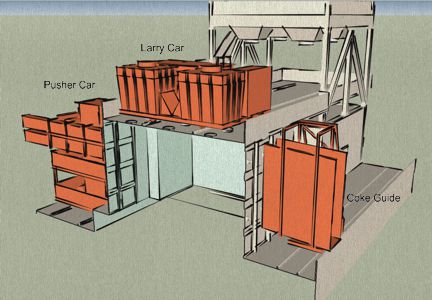

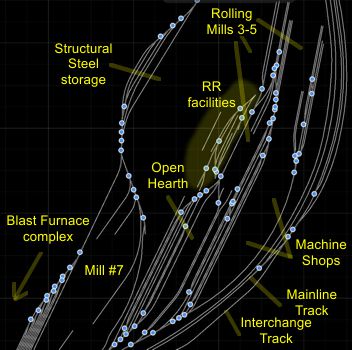

4/29: Progression on the Massillon extension of Ohio Steel continues where the steel mill has been passed over to continue populating the remainder of the route while the steel mill is constructed. Noteworthy news includes the Massillon

Steel Mill owned by Republic is being expanded to include a blast furnace, ore pit, ore bridge, coke ovens, etc. Recently pictures and articles of the Massillon Mill have been found and the information is being incorporated into the

route. Pretty exciting stuff as these finds now double the size of the mill. At the same time it's exciting to be able to see the end of the route from where I'm working at presently, just north of Massillon. The Massillon extension

has also been mentioned in the latest Railworks newsletter. The ETA mentioned in the newsletter was established before the significant find of a blast furnace at Massillon and the additional buildings to be constructed for the blast

furnace may delay the release of the route.

|